Medical Wire: Precision Engineering for Life-Saving Applications

Medical wire is a cornerstone of modern healthcare, enabling critical procedures and devices that save lives and improve patient outcomes. As a specialized product, medical wire is meticulously designed and manufactured to meet the stringent requirements of the medical industry, adhering to standards such as ASTM F899 and ASTM F138. Its biocompatibility ensures it integrates safely with the human body, making it indispensable for applications ranging from surgical sutures to implantable devices. At Sunset Wire, we pride ourselves on delivering high-quality medical wire tailored to the unique demands of healthcare professionals.

What is Medical Wire?

Medical wire is a highly specialized type of wire engineered for use in medical applications, procedures, and devices. Unlike standard industrial wire, medical wire is crafted with precision to ensure it meets rigorous safety, performance, and regulatory standards. Its defining characteristic is biocompatibility, meaning it does not provoke adverse reactions when in contact with human tissue or bodily fluids. This makes it suitable for both temporary and permanent applications within the body.

The manufacturing process for medical wire involves strict quality control, precise tolerances, and the use of materials like stainless steel (notably 316LVM) that comply with standards such as:

- ASTM F899: Covers stainless steels for surgical instruments, ensuring strength, corrosion resistance, and suitability for medical use.

- ASTM F138: Specifies 316LVM (low-carbon, vacuum-melted) stainless steel for surgical implants, emphasizing biocompatibility and corrosion resistance.

These standards ensure that medical wire performs reliably in demanding environments, from operating rooms to long-term implants.

Key Applications of Medical Wire

The versatility of medical wire makes it a critical component in a wide range of medical applications. Its ability to be drawn into fine diameters, maintain strength, and resist corrosion allows it to serve in both minimally invasive procedures and complex implantable devices. Below are some of the primary uses:

Surgical Sutures: Medical wire is used to create sutures for closing wounds or surgical incisions. These wires are often made from stainless steel or other biocompatible materials, offering high tensile strength and flexibility to secure tissue without causing irritation or rejection.

Stents: Stents, used to keep blood vessels or other passages open, rely on medical wire for their structure. The wire’s precision and durability ensure stents can be deployed accurately and withstand the body’s dynamic environment, particularly in cardiovascular applications.

Catheters: Catheters, which deliver fluids or guide other instruments, incorporate medical wire to provide flexibility and navigational control. The wire’s smooth surface and biocompatibility reduce the risk of tissue damage during insertion and use.

Electrode Leads: In devices like pacemakers or neurostimulators, medical wire forms electrode leads that transmit electrical signals. These wires must be highly conductive, biocompatible, and resistant to fatigue, ensuring reliable performance over long periods.

Electrode Leads: In devices like pacemakers or neurostimulators, medical wire forms electrode leads that transmit electrical signals. These wires must be highly conductive, biocompatible, and resistant to fatigue, ensuring reliable performance over long periods.

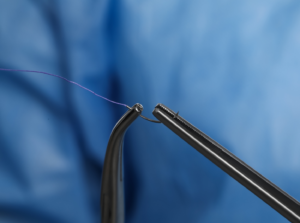

Guidewires: Guidewires are essential for navigating catheters or other devices through the body’s vascular system or other pathways. Medical wire used in guidewires is designed for flexibility, strength, and precise control, enabling doctors to perform minimally invasive procedures with accuracy.

Implantable Devices: From orthopedic implants to dental devices, medical wire is a key component in permanent or semi-permanent implants. Its ability to withstand corrosion and mechanical stress makes it ideal for applications like bone fixation wires or spinal implants.

Sizes and Specifications

Medical wire is available in a range of sizes to suit diverse applications, typically ranging from ultra-fine diameters (as small as 0.001 inches) to larger gauges depending on the device or procedure. At Sunset Wire, we offer medical wire in diameters from 0.02 inches to 0.625 inches, with custom sizes available to meet specific requirements. The wire can be supplied in coils, spools, or straight lengths, ensuring versatility for manufacturers and healthcare providers.

Material Specifications

The most common material for medical wire is 316LVM stainless steel, specified by ASTM F138, due to its exceptional properties:

- Biocompatibility: Safe for prolonged contact with the body.

- Corrosion Resistance: Resists degradation in bodily fluids.

- Low Carbon Content: Reduces the risk of sensitization and improves weldability.

- Vacuum-Melted: Enhances purity and minimizes inclusions, critical for implants.

Other materials, such as titanium or nitinol (a nickel-titanium alloy), may be used for specialized applications like shape-memory stents or flexible guidewires. Sunset Wire ensures all materials meet or exceed ASTM F899 and ASTM F138 standards, with additional certifications for medical device quality management.

Mechanical Properties

The mechanical properties of medical wire vary by material and application but typically include:

- Tensile Strength: High enough to withstand stress without breaking.

- Flexibility: Allows bending without fatigue, crucial for guidewires and catheters.

- Surface Finish: Smooth to minimize tissue trauma and ensure ease of insertion.

These properties are tailored during manufacturing through processes like cold drawing, annealing, or coating to meet the precise needs of each application.

Why Choose Sunset Wire for Medical Wire?

At Sunset Wire, our expertise in precision wire manufacturing ensures that our medical wire meets the highest standards of quality and performance. Our AS9100 and other certifications reflect our commitment to excellence, making us a trusted partner for medical device manufacturers. Key advantages include:

- Custom Solutions: We offer tailored sizes, materials, and finishes to meet unique project needs.

- Stringent Quality Control: Every batch is tested to comply with ASTM F899, ASTM F138, and other relevant standards.

- Fast Turnaround: With minimum lead times of 1-2 weeks, we deliver critical components on time.

- Biocompatible Materials: Our 316LVM stainless steel and other alloys are optimized for safety and durability.

Whether you’re developing a new catheter, designing an implantable device, or sourcing wire for surgical instruments, Sunset Wire provides the reliability and precision you need.

Medical wire is a vital component in the healthcare industry, enabling life-saving procedures and innovative devices. Its biocompatibility, adherence to ASTM F899 and ASTM F138 standards, and versatility make it indispensable for applications like sutures, stents, catheters, guidewires, electrode leads, and implants. At Sunset Wire, we combine advanced manufacturing techniques with a commitment to quality to deliver medical wire that meets the exacting demands of the medical field.

For more information or to discuss your medical wire needs, contact the experts at Sunset Wire today. Let us help you bring your medical innovations to life with precision-engineered wire solutions.